Il partner giusto per le tue saldature e lavorazioni meccaniche

WE.MA. Srl (Welding Machining) was set up in 2003 as a company specialised in welding, mechanical structural metalwork and machine tool processing.

Enthusiasm, tenacity and flexibility have made WE.MA. the perfect partner for the research and development of special projects commissioned by customers. The company only works with meticulously selected suppliers and only uses top quality raw materials.

The company’s Mission is founded on the achievement of Customer satisfaction, through the efficient management of relationships based, first and foremost, on respect, common sense, determination and team spirit. Although these may be simple terms, they are of paramount importance because they are the fundamental principles governing a way of working, living and relating with others. The main objective of WE.MA. is to become a continuous reference point for the Customer.

This is why WE.MA. continues to grow, by optimising its human resources, through continuous innovations in technology and machinery, by reducing costs, through the development and management of an efficient Quality system and by expanding its product range.

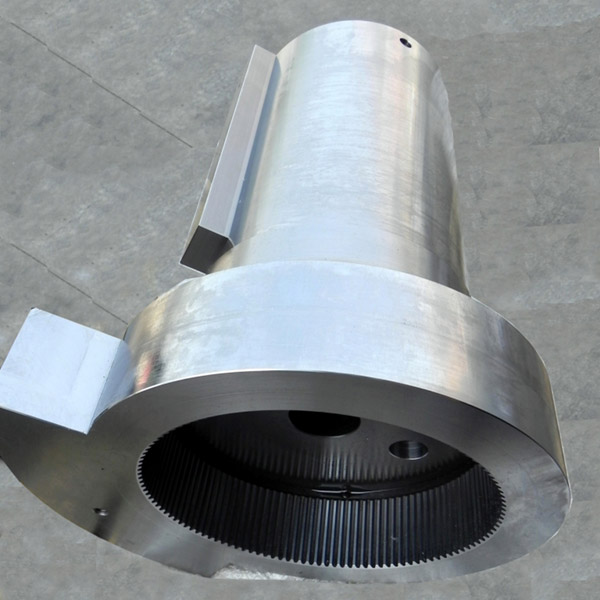

Our machines allow us to guarantee a standard of work that is professional, complete and hard-wearing.

The welding processes are in compliance with procedures as attested by the positive outcomes of testing, and they are monitored constantly. WE.MA. imposes high quality standards on all of the work processes carried out, including those handled externally, in order to be able to guarantee the characteristics of the final product. The design, supplied by the customer, is the fundamental departure point for the development of the product to be manufactured: we discuss and assess the design project of each individual component with the Customer in order to be able to rectify any design errors and incorporate integrations, modifications and improvements. Discussions may concern an actual “part”, a prototype, and the evaluation of feasibility and costs.

WE.MA. only outsources work processes to reliable companies qualified to carry out the work required.

The customer, on an approval basis, has full control of the workflow.

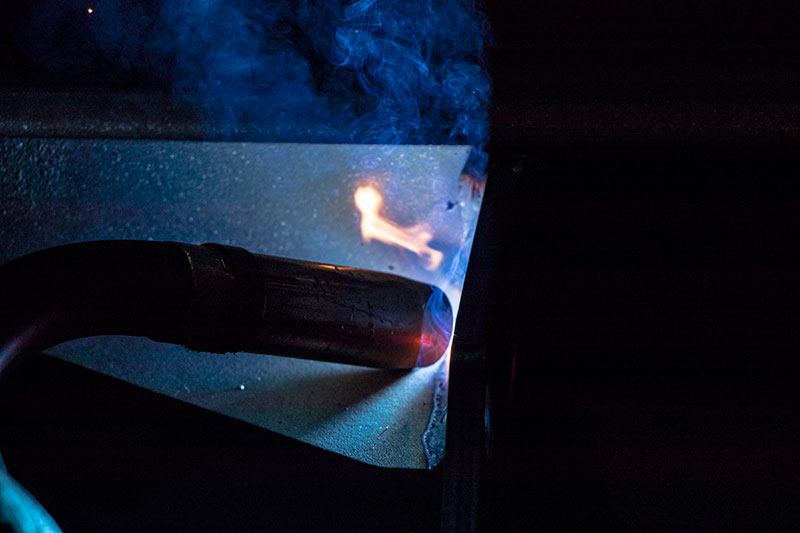

Our company uses as its standard a welding process that has been qualified through ISO 3834.2 2006 certification and its welders are qualified and certified in accordance with UNI EN and ASME IX.

Welder qualification serves essentially to give proof of their skill and ability in the execution of permanent joints.

Certification is an acknowledgement of the professionalism of your welders and operators; following the path that leads to certification, they acquire greater theoretical knowledge and practical ability, they feel that they have been justly rendered responsible for their work and as a result they are more motivated when carrying out a special process that has a major impact on the quality and safety of the final product. All this leads to greater reliability in terms of their work performance. The certification of the welders, together with that of the welding process, will demonstrate your orientation towards quality and your customers will have evidence of this, also on paper.

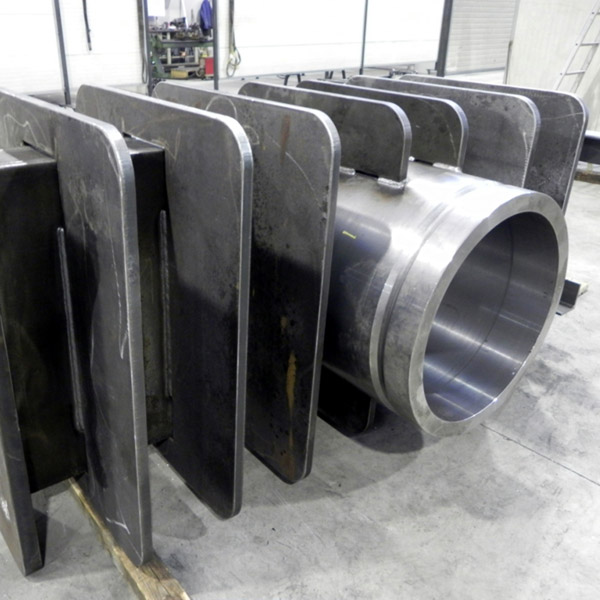

In this department, welding processes are carried out on all kinds of components, from very small to extremely large. The following welding processes are carried out: continuous wire, CO2, submerged arc, electrode and TIG.

In the course of recent years, the company has specialised in a variety of fields. We have the capacity to manufacture numerous diversified structural metal parts for a wide variety of different sectors, such as:

· electromechanical sector

· lifting equipment sector

· machine tools sector

· packaging sector

· the agricultural and earth moving machinery sector

· metal construction work for the building sector

· industrial automation systems: automated warehouses, lifting equipment, conveyors and elevators for small and large dimensions

· storage systems, roller conveyors

· structural metalwork for drying systems, for systems for the drying and cooling of brickwork

· structural metalwork for motorway barriers, machining of columns and beams of all sizes and lengths

· structural metalwork for the construction of iron structures for the building sector: trusses, shed structures, etc…

· structural metalwork of all kinds, from the simplest to the most complex.

30 JIB CRANES, MAXIMUM CAPACITY 1000 KG.

7 BRIDGE CRANES, MAXIMUM CAPACITY 10000 KG.

1 HYDRAULIC C-NECK PRESS, 2 HYDRAULIC PRESSES, MAX 4.5 x 2 MT

1 LINEAR SUBMERGED ARCH SYSTEM OR WITH ROTARY PLATE

6 FORKLIFT TRUCKS, CAPACITY UP TO 50 QUINTALS

1 SIDE FORKLIFT TRUCK, CAPACITY 40 QUINTALS

1 AMADA HA400 BAND SAW

1 BIANCO 370 AF CNC BAND SAW

1 FORTE SBA 421 S BAND SAW

1 MANDELLI OVER8000 MACHINING CENTER, STROKE 9800x900x2000

1 MANDELLI 1000/1 MACHINING CENTER, ROTARY TABLE, STROKE 1400x900x700

1 MANDELLI REGENT MACHINING CENTER 1200, STROKE 2700x1100x1000

1 MT14 FIXED COLUMN MILLING MACHINE MACHINES TOOLS

1 MECOF FIXED BED MILLING MACHINE L 8000

1 ARNO UNIVERSAL MILLING MACHINE, STROKE 1250x450x280

1 EMA F50 / 1006 RADIAL DRILL

1 GRAZIANO SAG 180 LATHE

1 TOVAGLIERI GT700 LATHE

1 SUBMERGED ARC WELDING SYSTEM WITH MOBILE BRIDGE

1 DOUBLE TORCH CIRCULAR WELDING SYSTEM

1 SINGLE TORCH CIRCULAR WELDING SYSTEM

2 CAST IRON PLATES, MAXIMUM L 5200 mm

11 ESAB MIG/MAG WIRE WELDERS UP TO 400 A

5 FRONIUS 4000 PULSE WELDING MACHINES

2 ROTARY TABLE POSITIONERS KG.230

1 GAMMA 1000 TUNNEL TURBO-MECHANICAL SHOT BLASTING MACHINE

1 MILLENIUM PAINTING SYSTEM, MT 14x4 CABIN

Our green journey began in 2018 when we dedicated ourselves to the self-production of clean energy by installing a photovoltaic system that currently covers 40% of our energy needs.

The goal is to increase its production capacity by 2026, optimizing self-consumption thanks to the use of storage batteries.

Why we chose to collaborate with Treedom.

Together with its working group, Treedom gives companies and individuals the opportunity to purchase individual trees with the aim of helping the planet reduce harmful CO2 emissions.

But the good news doesn't end there: the trees are planted and grown by local farming communities who, in addition to gaining a job opportunity from this activity, have the opportunity to keep the fruits, guaranteeing both a food resource and a source of income to support their income.

We strongly believe in the possibility of making the world more supportive and eco-sustainable and we will do our utmost to improve ourselves in every aspect.

If you like, you can personally follow the project we have undertaken together with Treedom through our dedicated page and you will have the opportunity to verify every single plant we have invested in and how it will bring benefits both in environmental and social terms.

WE.MA. on the Treedom website

Companies belonging to the mechanical engineering sector have decided to build a network in order to be able to offer, together, a complete service. by pooling their skills and expertise. This is the Piacenza Mec Group, a multi-sector network of enterprises operating in a territory that has always been the cradle of “Made in Italy” mechanical excellence.

Strada Dogana Po 2/N

29015 Castel San Giovanni (PC)

P.IVA 01391760335

R.E.A. 158504

Tel: 0523-865085

Fax: 0523-863000

E-mail: info@wemasrl.it